Conformal coating

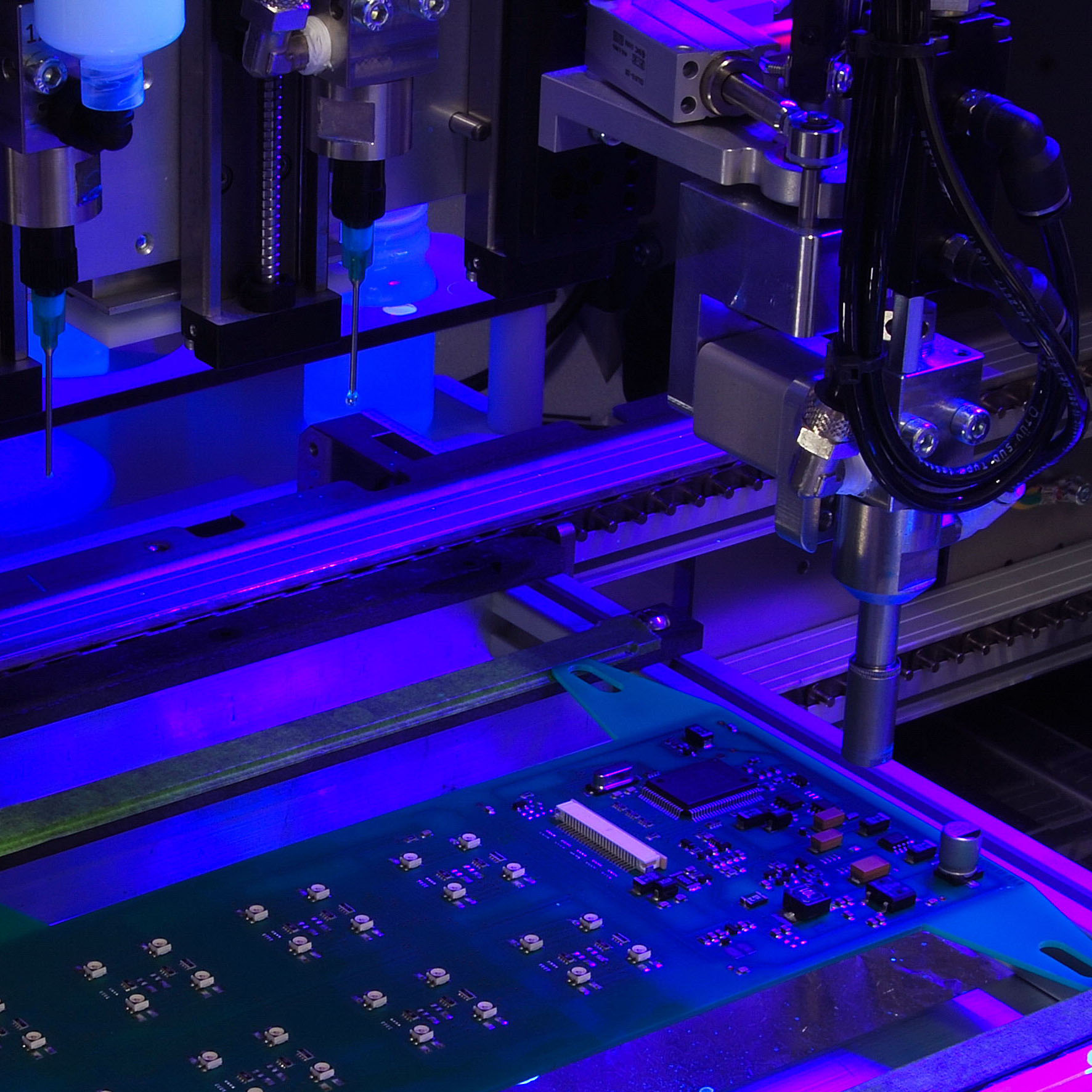

A conformal coating is a polymer material that is applied to a printed circuit board to protect it from a wide variety of contaminants.

The conformal coating provides an insulating layer that can protect the printed circuit board from solvents and other external environmental influences to which the printed circuit board is exposed during its life cycle.

A conformal coating is resistant to humid air, which significantly reduces the risk of leakage currents, tin whisker growth, etc. This risk has only increased by decreasing the pitch and placing components closer together.

Potting & encapsulation

In the potting and encapsulation process, a printed circuit board is placed in a housing or in a silicone mold and then it is filled with a two-component resin. The connections, controls, sensors and other external signalers are not poured in during the potting and encapsulation process and cannot affect the functionality of the control in a negative way. The sensitive logic circuit of the printed circuit board is protected in this way against environmental influences and mechanical stress.

Sub-assembly

The conformal coating or potting of a printed circuit board is often one of the last steps in the assembly process. In order to leave this process running as efficiently as possible, we can take care of the entire assembly. We have an extensive supplier network and extensive experience in manufacturing products for various industries. We provide insights to produce your products more efficiently and thereby save costs.