In the years that we offer our services to our customers, we have seen many printed circuit boards with sometimes great challenges. Often these challenges are also associated with higher costs and an increased risk of bad boards during production. Because many electronics designers do not always know what to take into account during the production process, we share our experiences. In many cases, these will be relatively minor adjustments that can yield significant long-term savings during the production process

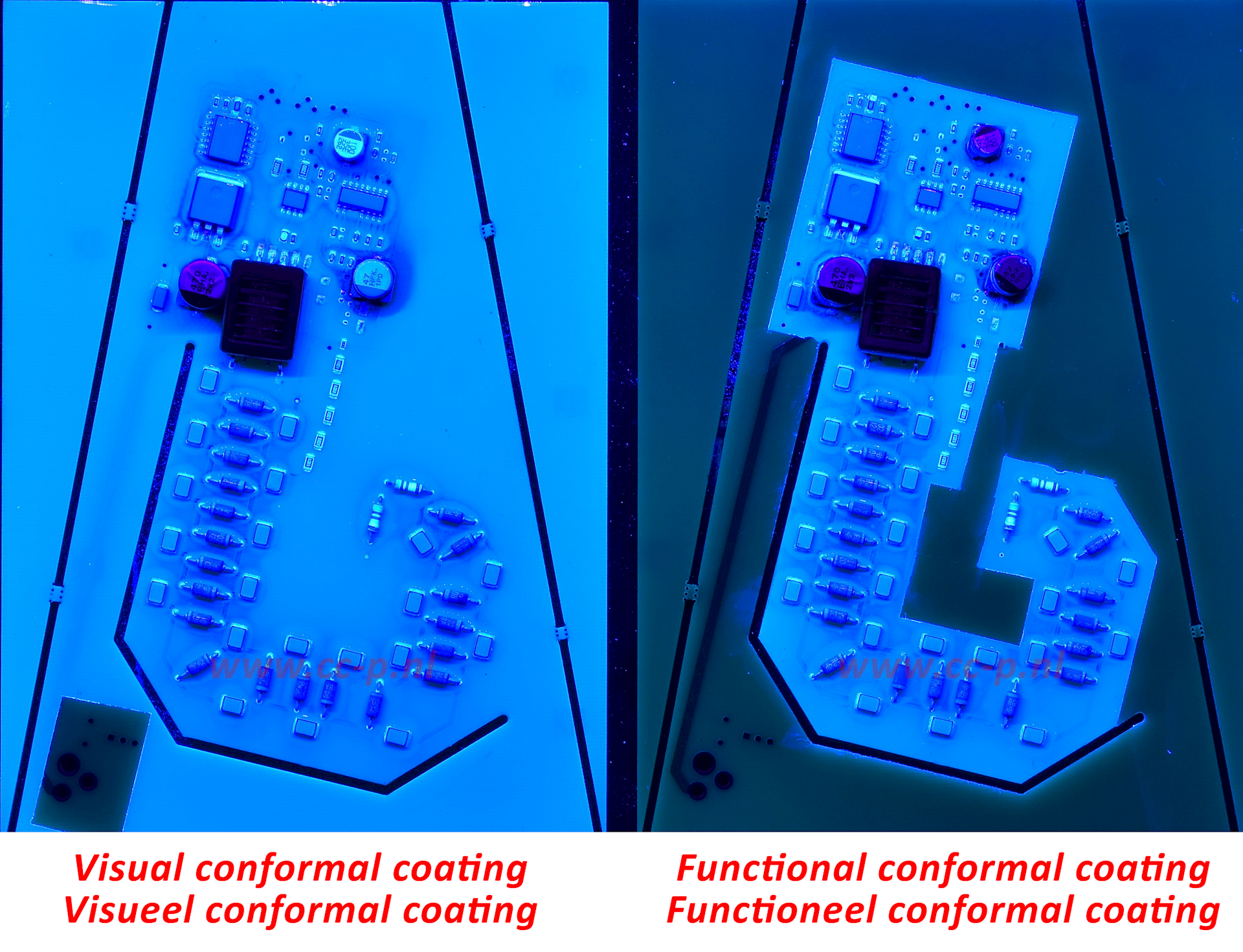

Functional or visual conformal coating?

With the conformal coating of an electronic board, we make a distinction between functional or visual coating. The difference between the two conformal coating methods is in the approach of the board. With functional conformal coating, we indicate on the coating plan which segments of the board must be coated and which segments absolutely must not be coated. Coating material may be applied to the space that remains, but it is not a requirement. This method of coating is generally related to machine conformal coating.

With visually conformal coating, we indicate on the coating plan which segments of the board should not be coated. This way of conformal coating is related to manual and machine conformal coating.

Conformal coating plan

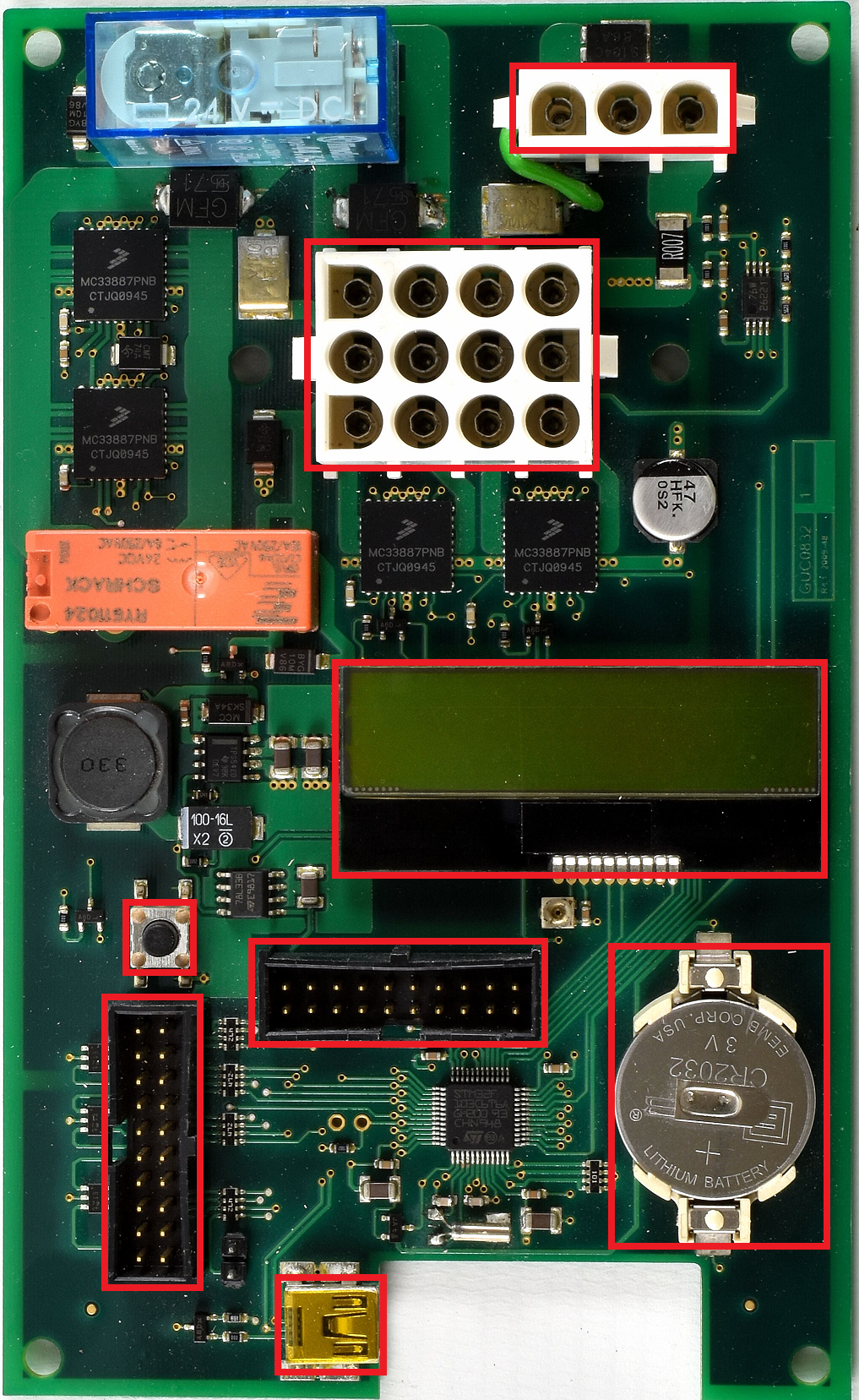

Before the PCB can be coated, a conformal coating plan must first be drawn up. This plan must indicate which components and/or segments of the PCB should or should not be coated. The plan must also state which coating material must be applied to the PCB, which sides must be coated (top and/or bottom), the dimensions of the PCB and the name. This information is relatively easy to compile in a Word document and contains the basic information required for conformal coating. For PCBs that must comply with quality systems, we draw up a more extensive plan together with the customer.

TIP: you can take a picture of the PCB and make colored rectangles with Windows Paint to indicate on the PCB which components and/or segments of the PCB should not or should be coated.

If you also have a tip or advice. Mail it to us through our contact form!

The following brands are a selection of our material suppliers