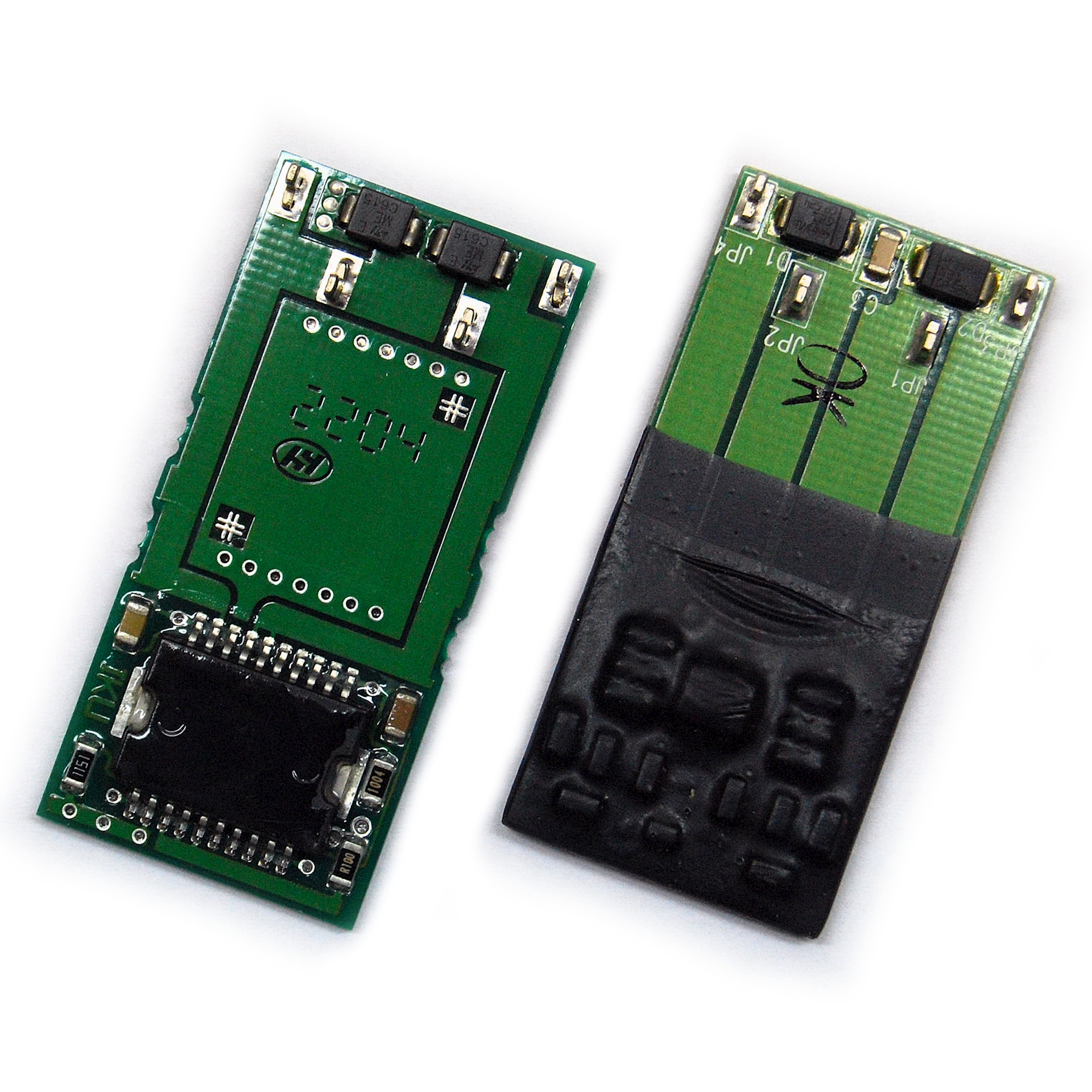

A conformal coating is a protective layer that is selectively applied to a printed circuit board to protect it from external environmental influences. In the conformal coating process, a thin, non-conductive coating is applied to the printed circuit board by spraying, dipping or pouring. This coating layer is applied selectively so that connections, controls, sensors and other external signalers do not affect the functionality of the printed circuit boardl. Thanks to the conformal coating, the solder joints of the sensitive, logic circuit of the printed circuit boards are protected against corrosion. The life of a printed circuit board is extended by the coating and the operating reliability of the printed circuit board is significantly improved.

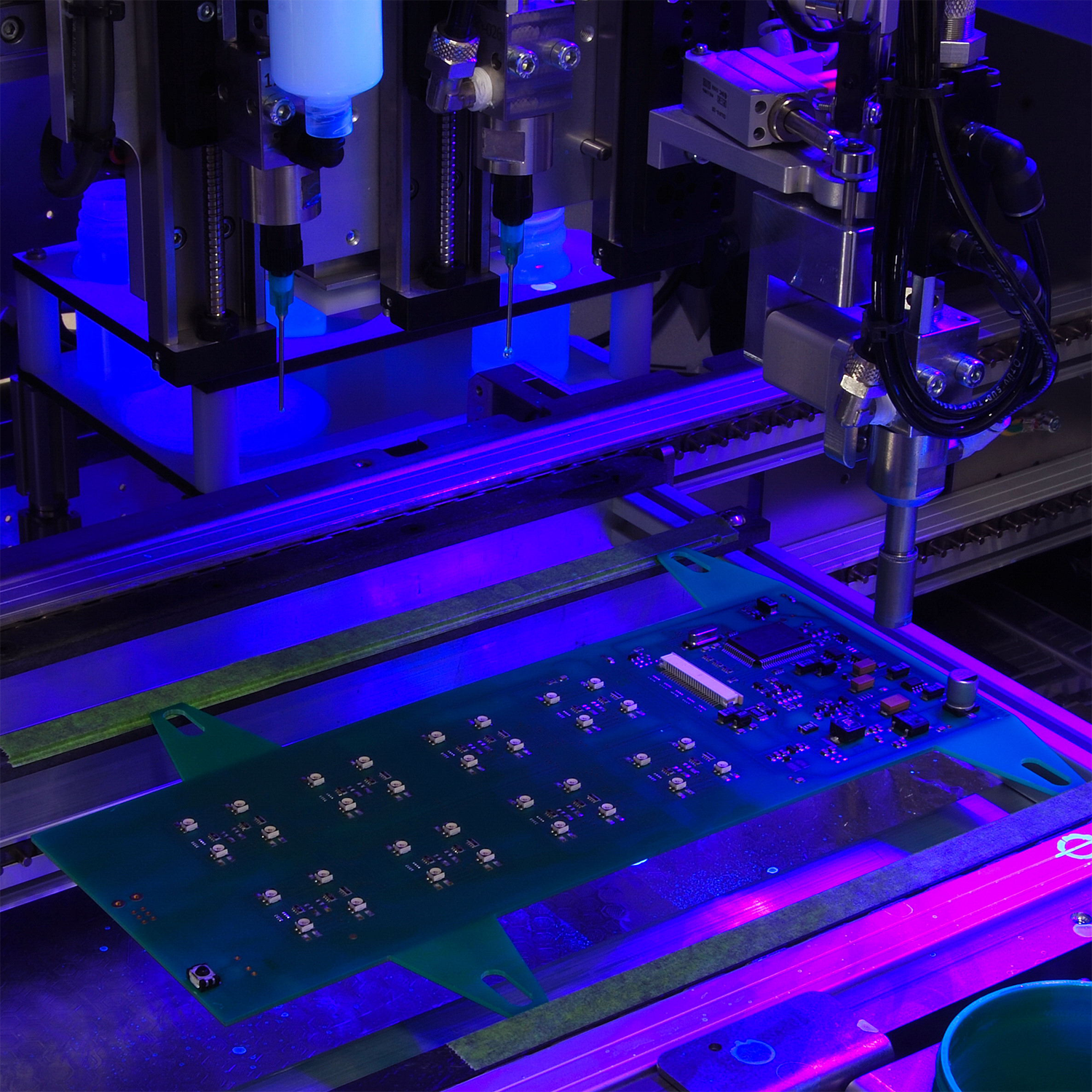

Selective conformal coating

In the selective conformal coating process, the coating is applied to the printed circuit board by means of a robot. The robot sprays the coating material with high accuracy in those places where the PCB must be protected. This way of coating is also called functional conformal coating because only material is applied to the joints.

Spray coating

Applying a conformal coating by spraying is often done with printed circuit boards with various connections, controls, sensors and other external signaling devices or with printed circuit boards that have to be provided with a thin conformal coating. These components are shielded during the production process, so that the functionality of these components cannot be negatively affected by the conformal coating. The layer thickness of a conformal coating, which has been applied by spraying, is relatively thin, which has the advantage that it is therefore less perceptible. The application of the conformal coating requires the necessary expertise. Shading of high components negatively affects an even distribution.

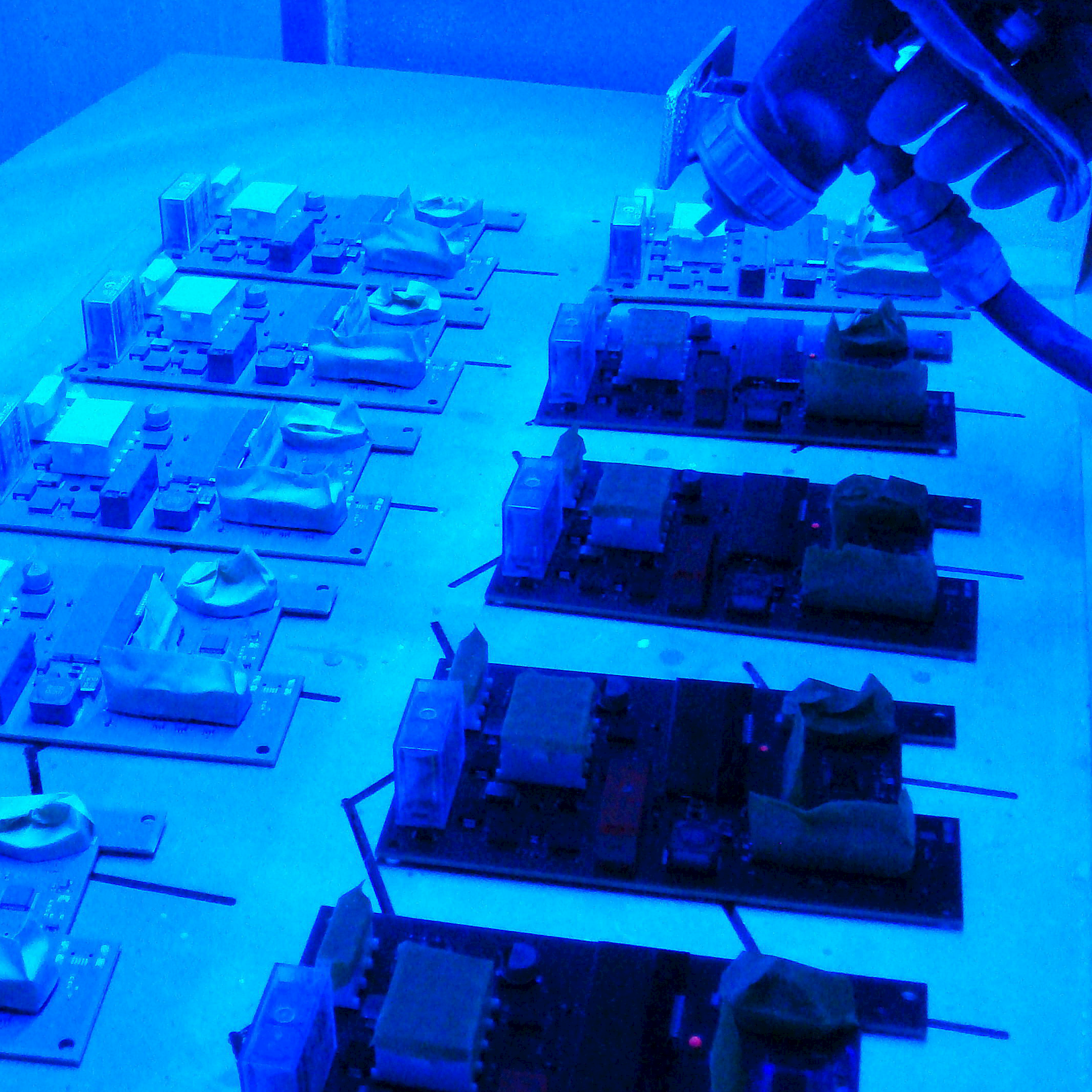

Dip coating

The application of a conformal coating by means of dip coating is often done with printed circuit board with few connections, controls, sensors and other external signaling devices or with printed circuit boards that have to be provided with a thick conformal coating. With dip coating, the printed circuit board is completely immersed in a bath with coating material. When the control comes out of the coating material bath, the excess material will drain and the coating will slowly cure. With this method it is difficult to shield specific components. The layer thickness with dip coating is relatively thick and is determined by the various process variables. Applying the conformal coating is simple, but proper shielding of specific components requires the necessary expertise.